Packaging of fresh produce

Packaging is commonly used for transport, storage and sale of perishable products. It is a broad concept that can be applied to a single product (e.g. fresh-cut vegetables) or to consolidate a bulk product (e.g. cardboard boxes on a pallet). Packaging is not used solely for marketing reasons, a packaging concept fulfils one or more specific functions essential for the preservation of perishable products.

The extended distribution chains and the many different processing methods applied to perishable products are only possible thanks to the use of packaging concepts.

To wrap or not to wrap; that's the question

Although packaging technology is used with great success for decades, a new challenge is arising nowadays. How can we make packaging more sustainable and circular?

One of the simplistic solutions is to ban the use of fossil-based packaging for perishable products. This solution may match the needs of a small-scale chain, it is however not suitable for large commercial chains.

The use of biobased or recycled plastic material will help to realize more sustainable and circular packaging concepts. These novel materials do bring new constraints that need to be addressed for the specific market of perishable products. A new equilibrium need to be found between product needs and new sustainable packaging concepts.

Overview most important packaging functions

Basic functions of packaging

Risks on product damage by misuse of pacakaging

| Property packaging | Example of misuse | Risk |

|---|---|---|

| Moisture barrier to limit dehydration | Too little ventilation | Mould and rot |

| Mechanical protection | Too low packaging rate | Damaged product |

| Enable heat dissipation of product through ventilation holes | Too much perforation/ too many ventilation holes | Dehydrated product. Collapse of boxes due to low firmness of the packaging |

| Enable heat dissipation of product through ventilation holes | Stacking too tight or occlusion of holes | Accumulation heat produced by product and thus loss of quality |

| Modified air to limit product activity and extend shelf life | A non-optimal air composition due to too high or fluctuating temperature | Off-taste, internal quality problems |

| Modified air to prevent discoloration | A non-optimal air composition due to too high or fluctuating temperature | Browning caused by fermentation |

| Modified air to restrict microbial growth | A non-optimal air composition due to too high or fluctuating temperature | Discoloration and unwanted microbial growth |

More about packaging and preserving quality

How to design an optimal packaging

-

Boxes with strawberries in a box. Photo by Chatchai.wa/Shutterstock.com Optimizing processes and distribution

- Storage at the lowest possible temperature that is safe for the product is the key to also have a successful packaging.

- Pack only the best product quality and avoid fluctuations in product quality all year round.

- Minimize processing, handling and any unnecessary steps that can could cause mechanical damages.

- Storage at the lowest possible temperature that is safe for the product is the key to also have a successful packaging.

-

Packaging research lab at WFBR. Photo by Verse Beeldwaren Know and understand: measure

- Regularly measure the respiration rate of your (processed) product.

- Define the transpiration rate of the product as well as the acceptance limit for dehydration symptoms.

- Define which quality criteria are essential for your product such as discoloration, off-odor and food safety.

- Regularly measure the respiration rate of your (processed) product.

-

Packaging researcher at work. Photo by WUR Choose the best packaging option

- Use a mathematical model to match the need of your perishable product to the packaging specifications.

- Select the packaging material to meet the most important quality criteria; apply innovative technologies (laser micro-perforation, scavenger) to optimize your packaging concept.

- Avoid over- and non-functional packaging.

- Use a mathematical model to match the need of your perishable product to the packaging specifications.

Trends in packaging

There are various trends and developments in the field of packaging. Changing consumer needs have a major impact on both the product offered and the packaging. Important underlying trends at the moment are, for example, growth in the convenience segment and the emergence of new sales channels such as e-commerce and on-the-go consumption. Food safety regularly receives more attention due to outbreaks of certain diseases. In addition, we also have to deal with climate goals and there is growing social resistance to the use of plastic packaging materials. These trends present continuous packaging challenges, as well as opportunities for companies in the sector. For example, look at the rise of ready-to-eat vegetable meal packages and the rise of organically grown products.

In terms of sustainability, the aim is to achieve a more circular economy in which raw materials are conserved. This instead of the current linear economy, in which raw materials are extracted, products are made and then partly thrown away. This creates a hugh amount of waste and it depletes the earth's resources. Packaging also plays a role in this. For food packaging, it is difficult to achieve completely circular packaging because packaging must be food-grade, which makes it difficult to reuse food packaging. Worldwide, various countries have their own legislation and requirements regarding the sustainability of (food) packaging. The EU also has various guidelines within which countries operate.

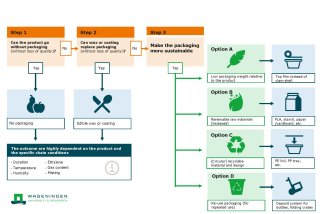

Guide for sustainable packaging

Explanation guide

Determining the sustainability of packaging

WUR experts can help with issues related to sustainable food packaging. Various projects are being carried out in this area. For example, read more about the Wrap or Waste project here. Or read more about what WUR can mean for companies in this area.