Understanding quality traits of fruit

As consumers we have all experienced the joy of eating good and bad quality fruit. There is no arguing for taste, but what is “quality”? From farm to fork, specific quality traits are used to determine harvest maturity, for sorting and grading purposes, to check and predict how quality develops in the chain, for food safety regulations compliance and to estimate the use by consumers. While some of these traits can be determined without damaging the fruit, others require the fruit to be sampled.

External quality aspects

Some quality aspects can already be determined by looking at the outside of the fruit. Such aspects are for example the colour of a fruit, the shape and size of a fruit, or the presence of defects or disorders.

Internal quality aspects

Some quality aspects cannot be seen at the outside of the fruit. Examples are firmness, mealiness, juiciness, crunchiness, dry matter content, weight, starch content, sweetness, acidity, aromas and flavours, internal defects and disorders. Some of these quality aspects can be measured in a non-destructive way, but for others, the fruit has to be cut to assess it.

Quality measurements

Typically, quality traits can be measured either non-destructively (by looking, feeling, weighing, smelling) or destructively (by cutting, tasting, grinding).

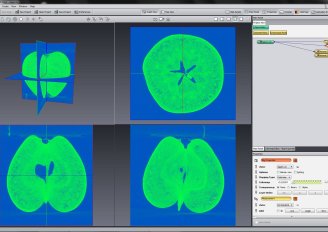

In recent years, more and more sensors are becoming available to measure fruit quality non-destructively. This enables full batch sorting on specific aspects and has the great advantage that fruits can still be sold after inspecting them.

Well-known examples of non-destructive quality measurement methods are the use of cameras (for colour and external defects) and NIR or hyperspectral sensors (for internal damage, sugar and dry matter content). Ethylene or other (aroma) gas detection sensors are used for batch monitoring in storage and transport as marker for ripening, and/or defects/disorders.