Temperature management

An optimal temperature is mostly the first requirement to maintain a good quality of horticultural produce after harvest. Refrigeration is an effective method of preserving the quality of fresh produce. The cooler temperatures extend the storage life by reducing various processes such as respiration, water loss, colour change, and decay. The produce should however not be stored below their critical temperature. Chilling injury may then occur. This would result in risks on various quality problems such as weakened tissue leading to discoloration and increased risk of decay. The optimum temperature varies per commodity and should be controlled throughout the whole fresh supply chain.

Directly to

Crops and varieties

Fresh horticultural produce benefits from low temperature to maintain their quality. But the optimal temperature can vary greatly between crops. Sources such as postharvest websites can be consulted to find the optimal temperature ranges for each crop. Nevertheless, the optimal temperature can vary with the variety, the area where the product was grown, the season of harvest and the harvest maturity. Further fine-tuning of the optimal temperatures should therefore be based on research in combination with practice experience.

Quality and temperature

How long a product retains its quality strongly depends on the temperature. Cooling the product after harvest slows down the ripening and aging process. Cooling slows down the respiration of the product. Microbiological diseases caused by fungi and bacteria also develop many times more slowly and moisture loss is lower.

If products are kept too cold, cold damage can occur. Examples are discolorations or too little flavor development.

For a number of products, such as blueberries and cabbages, temperatures just above zero (0.5 to 1 °C) are ideal. But some varieties of apples, fruiting vegetables such as tomatoes and cucumbers, and tropical fruits such as mango and banana are sensitive to cold. They must be kept at higher temperatures, 4 or 14 °C, depending on the product.

If products are kept too cold, cold damage can occur. Examples are discolorations or too little flavor development.

For a number of products, such as blueberries and cabbages, temperatures just above zero (0.5 to 1 °C) are ideal. But some varieties of apples, fruiting vegetables such as tomatoes and cucumbers, and tropical fruits such as mango and banana are sensitive to cold. They must be kept at higher temperatures, 4 or 14 °C, depending on the product.

Temperature sum

The temperature is very relevant during the total fresh supply chain. A calculation related to this is the 'temperature sum' or, in other words, the 'total degree days'. The temperature sum is the accumulated temperature over a period of time. To calculate this, the average of the daily maximum and minimum temperatures is taken at each step of the chain. The temperature sum is the sum of the total daily averages. A higher temperature sum usually corresponds to a shorter remaining shelf-life. This rule is no longer valid when temperatures are too cold with possible consequences of chilling injury or freezing damage.

Damage because of too low temperature

Pre-cooling

Pre-cooling is used to remove product field heat rapidly after harvest. It is a basis for keeping good quality of vegetables, fruit and ornamentals in the cold chain. When the products are simply placed in a cold room, the temperature reduction of the produce will take a long time, usually days. There are several pre-cooling systems available to reduce the product temperature faster, usually within a few hours. The most widely used method of pre-cooling is forced-air cooling. Best known are tunnel-type fixed units where a fan is used to force the cool air through the load. The air flow is guided by canvas or polyethylene sheets (tarps) which are rolled over the top of the load (and down to the floor). Other fast methods are vacuum cooling, hydro-cooling, and the use of ice on the product.

Cold storage rooms

It is the function of a cold store to be able to store products at low temperatures. This can be for a short period of time, for example if the product has to wait a while before it is transported (buffering). There may also be long-term storage.

Most cold stores are designed to maintain a constant low temperature. The temperature sensor, which measures the air temperature in the cold store and allows for adjustment, is normally suspended in the return air stream that exits at the evaporator. In addition, it is wise to measure the product temperature (internally), this provides valuable insights into, for example, temperature differences in a cold store.

Optimizing the air circulation can minimize the temperature differences in the cold store.

Most cold stores are designed to maintain a constant low temperature. The temperature sensor, which measures the air temperature in the cold store and allows for adjustment, is normally suspended in the return air stream that exits at the evaporator. In addition, it is wise to measure the product temperature (internally), this provides valuable insights into, for example, temperature differences in a cold store.

Optimizing the air circulation can minimize the temperature differences in the cold store.

Refrigerated transport

The cold chain must be maintained from the moment of pre-cooling to the retailer. This can be challenging. A reefer container is usually used for sea transport of fresh products. A refrigerated truck for road transport. Refrigerated air transport is used less often.

It is important to realize that a reefer container and a refrigerated truck are designed to maintain, not lower, the temperature of the fresh product. It is therefore important to pre-cool the product before placing it in the reefer container or truck.

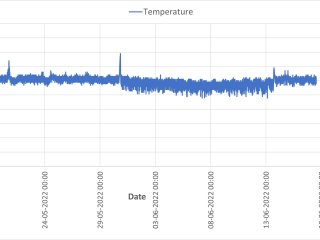

The load must be stacked in such a way that air circulation is sufficient everywhere, so that the temperature differences of the load remain small. Temperature loggers can be used to review the temperature profiles of the cargo afterwards.

It is important to realize that a reefer container and a refrigerated truck are designed to maintain, not lower, the temperature of the fresh product. It is therefore important to pre-cool the product before placing it in the reefer container or truck.

The load must be stacked in such a way that air circulation is sufficient everywhere, so that the temperature differences of the load remain small. Temperature loggers can be used to review the temperature profiles of the cargo afterwards.

Mixed loads

// Insert an image list with design: FK Wide

The optimum temperature may differ between the products. With mixed loads of these products, the temperature is therefore not optimal for all products. This need not be a problem for short-term storage. If mixed loads cannot be avoided, fruit and vegetables can be combined whose optimum temperature does not differ too much. Most tropical products are sensitive to cold and cannot be combined with products that absolutely need cold temperatures, such as strawberries and leafy vegetables. A problem that can also occur with short-term storage is that a product can be affected by the transfer of odors that are emitted by another product. Humidity and ethylene are also important.