Research Results

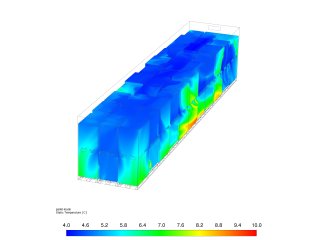

Perishables by rail -- temperature homogeneity in 45ft reefers

Europe experiences a growing interest in long distance rail transport of perishables. In this project we worked on the development of an improved version of a 45ft reefer for transport of perishables by rail to e.g. China. The gained insights are relevant to any transport modality.

About the research

A large number of climate chamber tests has been conducted: measurement of energy consumption, airflow and temperature in dozens of locations within stuffed reefer containers in many operating conditions imposed in a climate chamber. The collected data gave valuable insights and were used for Computational fluid dynamics (CFD) model calibration and validation. In-depth studies have been performed to unravel the insulation value of insulated 45ft reefers.

Scientific innovations

An advanced CFD model was set up to accurately predict airflow and temperature distribution in refrigerated transport equipment. Based on the CFD simulations a new air chute design is proposed for better temperature homogeneity.

A measurement methodology was developed and tested to measure the insulation value of individual container wall sections.

Relevance for sector

A 45ft reefer container has been developed which is better suited for (very) long distance rail transport than any earlier equipment: more uniform temperatures and access to further destinations without refuelling. Understanding of the key success factors helps adequate repetition in other applications.