Longread

Evaluating firmness

How to determine if fruit is ‘ready-to-eat’ or assess how long it should ripen before it reaches optimal ripeness? While colour may provide information on some fruits, almost all fruit will soften and develop an easy-to-chew texture that facilitates optimal flavour release. Here we will inform you on common mechanical techniques that are available to determine firmness and what to think about before using a certain technique to determine the ripeness of fruit. Finally, we provide the current limitations for evaluating firmness while dehydration of the fruit may be in play.

Importance of firmness measurements

Firmness is a key component of fruit quality. From the moment we pick up a fruit, we will already have formed an opinion on how ripe it feels. When we bite into the fruit, its firmness contributes to positive factors such as crispness, crunchiness and juiciness (with its associated release of flavour), as well as informs us of some negative factors such as bruises and mealiness.

Fruit firmness is influenced by a variety of factors, including fruit morphology, tissue structure (cell shape and orientation), cell-to-cell adhesion, cell wall thickness and composition, and turgor pressure. During ripening, changes in cell wall composition make a fruit softer and easier to bite into, while retaining sufficient texture to hold the bloated cells in place for the teeth to shear them open and release their sweet and juicy contents. Under some conditions, cell-to-cell adhesion weakens and causes the cells to slide alongside each other, which makes it difficult for teeth to shear them open and thereby leads to a mealy texture and loss of juiciness. Dehydration of the fruit causes the cells in the fruit to become less bloated and results in fruit that is softer to the touch, but still has hard cell walls, which leads to a tough tissue with little taste.

Assessment of firmness can be done qualitatively and quantitatively. For qualitative analysis and a direct link to the consumer, a trained expert sensory panel is often used. However, even though a trained expert taste panel is relatively consequent, it is not fully objective and, as such, not ideal for quantitative analysis. For objective measurements, mechanical devices are better, particularly those unaffected by an operator. Techniques that require a person to either hold the fruit in their hand or position a probe to take a measurement, generally will show differences between different operators and differences over time.

Mechanical methods to determine firmness are generally divided into two categories: destructive and non-destructive. Non-destructive methods can be graded based on the damage they cause the fruit, several devices that are branded as non-destructive may still damage the fruit. Examples of mechanical devices to determine the firmness of fruit are provided in the next overview and explained further in this longread.

Overview of mechanical firmness measurement methods

| Measurement method | Device/Technology | Unit | Sampling | Used in research or practice |

|---|---|---|---|---|

| MT-firmness | Penetrometer | Kg | Destructive | Both |

| Durometer | Durometer | Shore | (Non)-destructive | Practice |

| Compression | Texture analyzer | N mm-1 | (Non)-destructive | Research |

| Impact | Probe-deceleration | g-force | Non-destructive | Practice |

| Acoustic | Aweta | 10*6 Hz*2 g*2/3 | Non-destructive | Both |

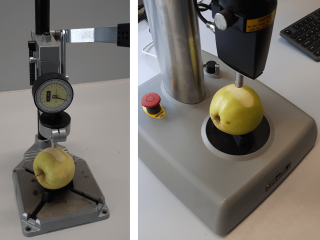

Magness-Taylor (MT) firmness is the golden standard to determine ripeness-related firmness in both research and industry. MT-firmness is a destructive method that relies on pushing a probe into the fruit flesh tissue and recording the maximum required force to do this. This maximum firmness mainly depends on the tissue structure and cell wall composition. As such, it is generally independent of dehydration, as the force required to break through the tissue and cell walls typically is larger than the turgor pressure. Commercial devices based on this method are called penetrometers, are available in both handheld and table-top formats and can be operated either manually or automated.

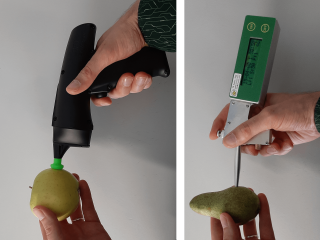

Durometers determine the force resistance of a tissue to a 3 mm standardized probe. While these devices are often branded as non-destructive, they generally bruise the fruit and, depending on the probe and fruit, can break the skin.

Compression-based methods determine the slope of a force-compression cycle. The amount of compression can be described by mm or strain (% of fruit diameter) and is defined by the technology. While some technologies stop the measurement after a certain amount of compression, others stop upon reaching a certain force. Depending on the amount of compression or force, the technology can be considered less or even non-destructive.

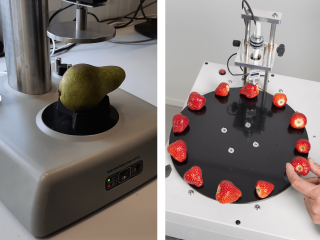

Impact-based methods typically determine the returning force of a probe that was launched at the fruit with a specific force. Lower probe returning speeds correlate to softer fruit. While this technology generally is non-destructive, the head of the probe can leave a mark, depending on the probe head, the force with which it is launched by the device and the skin and ripeness of the fruit it is launched at.

Acoustic firmness methods determine acoustic firmness by gently tapping fruit with a probe, recording the sound spectrum of this tap and computing this with the fruit weight. Typically, this method works well for fruits with a uniform shape.

Trends in practice

From these above-discussed devices, penetrometers are classically most used by growers. However, with the push to waste less fruit, non-destructive devices are gaining popularity, particularly towards the end of the supply chain. Among these, durometers seem most popular due to their ease of use, even though they may be considered a destructive method.

Influence of dehydration on firmness measurements

Over the last decades, research has shown that some non-destructive methods are relatively sensitive to dehydration-related changes in firmness. While ripening and dehydration both cause fruit softening, ripening leads to soft, tasty and juicy fruit, whereas dehydration leads to tough, tasteless and unexciting fruit. Preliminary results from laboratory research suggest that the less destructive methods are more sensitive to dehydration-related changes in firmness. In other words, destructive methods can measure fruit ripeness very well, but lead to food waste. Non-destructive measurements may not damage the fruit, but may provide incorrect information on the ripeness in cases where dehydration may occur, e.g. during transport or storage.

Surprisingly, non-destructive assessment of ripening-related firmness, independent of dehydration, has not been extensively explored. To fill in this knowledge gap, WUR is investigating the use of multi-sensor approaches to separate dehydration- and ripening-related firmness. In the short term, this may lead to workable solutions to assess both ripeness and dehydration status of fruit, while in long term we aim to develop a relatively cheap non-destructive method to assess ripeness and dehydration. Until that time, when using non-destructive firmness methods to determine fruit ripeness, it is important to make sure to work with fruit that has minimal dehydration levels.