NIR technology

Non-destructive fresh fruit quality analysis is of wide interest to stakeholders involved at various stages of fresh fruit chain. The need for quality assessment ranges from decision-making during harvest to monitoring fruit ripeness during long-term storage at high-end fruit storage warehouses. Several non-destructive sensing techniques are available for the quality analysis of fresh products. A key technique being promoted as useful in practice is visible (VIS) and near-infrared (NIR) spectroscopy

Light and wavelengths

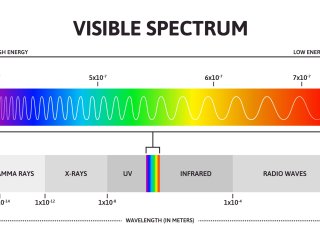

Light consists of a visible part and a non-visible part. The visible part has wavelengths from 400 nm (violet) to 700 nm (red). There is a non-visible part with wavelengths smaller than 400 nm, ranging from ultraviolet (UV) light to X-ray light. And there is a non-visible part with wavelengths larger than 700 nm, ranging from near-infrared (NIR) to infrared (IR) to microwaves and radio waves. The near-infrared bandwith is from 700 to 2500 nm.

NIR spectroscopy and product quality

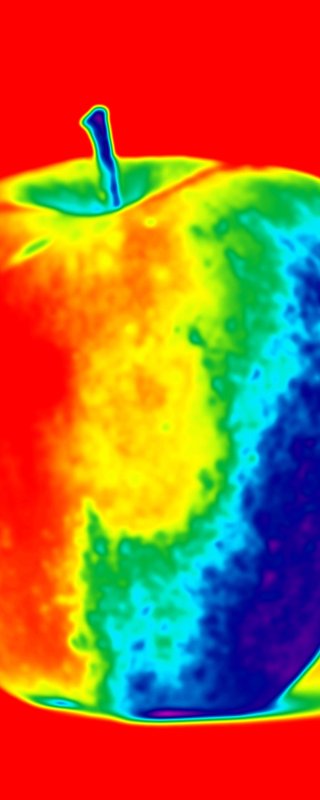

When you apply VISNIR spectroscopy, the product that you want to assess is irradiated with light in the spectral range of 400-2500 nm. For visible regions standard white light can be used while for the NIR, the halogen light sources are required. The light interacts, penetrates, scatters, absorbs and reflects from the product. The physicochemical state of the product determines how this happens.

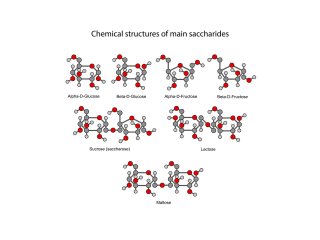

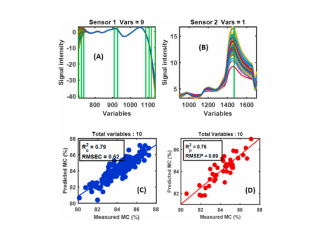

Chemically speaking, NIR light interacts with molecules in the product, specifically with C-H, O-H and N-H molecular bonds. Therefore, it can e.g. provide content information about water content, proteins, starch, sugars and cell walls. Differences in the reflected light of the NIR irradiation can therefore provide information about physical properties like surface texture, firmness or particle size. These properties are closely linked to fruit quality.

NIR spectrometers

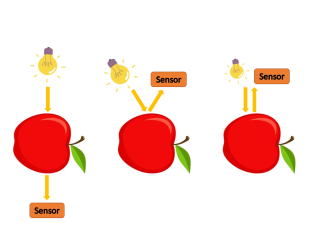

All NIR spectrometers have three main components: (i) a light source, often a tungsten halogen bulb, (ii) a wavelength selector, (iii) a sensor. The position of the light source to the measured product and sensor determines the measurement mode. Three main methods of using a NIR spectrometer exist:

- Reflectance measurements: the light source and sensor are positioned at an angle, often 45°, relative to the product.

- Transmittance measurements: the light source and sensor are placed at opposite sides of the product and the light that goes through the product is measured.

- Interactance measurements: the light source and sensor are positioned next to each other.

The selection of which measurement mode works best depends on the product. As a rule of thumb: light will typically not penetrate over 2-7 mm into fruits. For this reason, fruits are mostly measured in reflectance or interactance mode due to the dense flesh or thick skin.

Interpretation of NIR measurements

Do you want to know more? Please check out the link below. It will lead you to our white paper on Visible and Near Infrared Spectroscopy. It gives you insight of Vis-NIR spectroscopy for the use in the fresh-fruit chain as an affordable and non-destructive method to measure fruit-quality parameters.

Unfortunately, your cookie settings do not allow the social media element to be displayed. check your settings.