Dealing with ripening and ethylene

Ethylene is a gaseous compound also called the “ripening hormone”. It is present in the air in an extremely low concentration, often not even detectable. Yet this gaseous molecule is very important for the ripening of many fruits. Most fruits produce ethylene to start the ripening process. The effect of ethylene can be seen as positive if it leads to ripe and tasty products. Sometimes ethylene is even artificially added to regulate ripening. However, in many cases the presence of ethylene is undesirable. It limits the storage time if the fruit ripens too quickly and becomes overripe. This applies to products such as apple, apricot, avocado, kiwi, melon, papaya, pear, peach, plum and tomato.

Ethylene and ripening

Ethylene production by fruit

Ethylene sensitivity of fruit

Ethylene production and ethylene sensitivity are not always related. Products that do not produce large amounts of ethylene themselves can be sensitive to ethylene and therefore be affected by external sources of ethylene. An example is unripe kiwi. Look here for a table with a list of products and an estimate of the degree of ethylene sensitivity.

Ethylene during storage

Reducing the ethylene effect in practice

More information about situations in practice?

Ripening programs and ready-to-eat concepts

p

Ethylene sources and detection

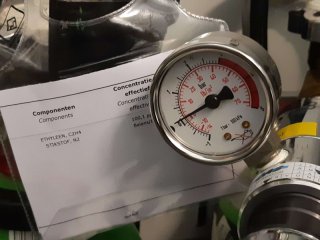

Measuring the ethylene concentration is strongly recommended. Ventilate if necessary. The advice for distribution centers is usually to stay below 500 ppb. There are several ethylene detectors on the market.

Measuring ethylene during transport

Unfortunately, your cookie settings do not allow the social media element to be displayed. check your settings.