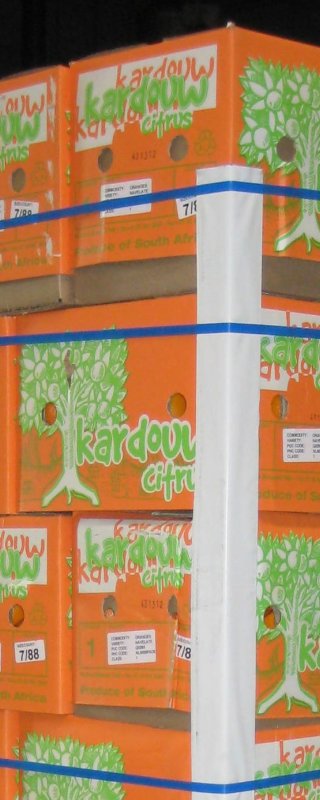

Cardboard boxes

Fresh produce must be packed in such a way as to protect the produce properly. Therefore strong protective packaging should be used. Different types of packaging are used depending on the produce but also on the market requirement. Fibreboard cartons are frequently being used. Waxed cartons are more suitable for storage and transport under conditions of high relative humidity.

Fitting well

Packaging keeps the product in convenient units and protects it during marketing. Boxes must be filled such that the products don’t have room to slide or roll. On the other hand, produce must fit without the need to use force, which could cause injuries and bruising.

Pay attention to overfilled boxes

The boxes should not be overfilled. The boxes should not be filled to such level that the next box, when stacking, touches product in the box underneath. It can cause damage on the outside of the product and bruises which may only be visible after cutting. Product should therefore not protrude above the top of the box.

Pay attention to poorly filled boxes

When products or smaller packages in the box are packaged too loosely, they can easily shift. This can cause mechanical damage to the product, such as bruising. For example, a lack of content in the box can occur when a part has been taken out for a small order.

Use of ventilation holes

Side-ventilation holes in boxes are required for forced-air cooling and shipment by truck. Boxes meant to be transported by reefer container must also have bottom-ventilation holes due to the vertical airflow in reefer containers. When holes are blocked, for instance by wrapping film, this may lead to a higher product temperature and loss of quality. The product in these boxes may need extra attention. Ventilation holes may also be restricted by produce or packaging material such as liners.