Transport practices for peppers

Transport of fresh products generally takes place in (refrigerated) trucks, reefer containers, or by plane. Checks and proper loading are always important to maintain good (temperature) conditions for the product during transport. For fresh products like peppers, refrigerated transport is often necessary. Trucks and reefers can maintain a low temperature, but do not have enough cooling capacity to lower the product temperature. Therefore, products must be pre-cooled before entering the refrigerated truck or reefer. During transport and waiting periods, the load must be well covered to protect against dust, sun and rain. Careful driving and handling are essential to prevent damage to produce from mechanical actions

Optimal transport conditions

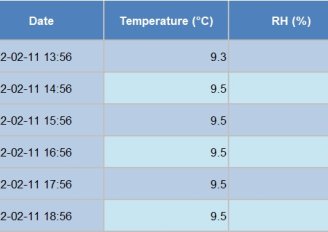

Transport of peppers from the field or the greenhouse to the packhouse should follow soon after harvest because it is essential that peppers, especially for overseas shipment, are cooled as soon as possible. After cooling in the packhouse, they can be transported further in (CA) refrigerated trucks or reefer containers. The best transport conditions for peppers depends on variety, maturity and transport time. For bell peppers concentrations of O2 and CO2 ranging between 2-5% with a temperature between 7-10 °C are often used. For hot peppers, concentrations of O2 and CO2 between 3-5% and 5-10% respectively, with a temperature between 5-10 °C. The optimum relative humidity ranges between 85-95% for hot peppers and 95-98% for sweet peppers.