Harvest practices for mango

Proper picking is a precondition to being successful in the rest of the supply chain. The performance of the pickers is therefore critical to deliver good quality mangos. First of all, picking at the right maturity is important to develop a satisfactory taste. Picking and further handling must be done carefully to avoid bruising and other damages to the product. The use of clean and suitable materials such as harvest crates also serves this purpose.

Harvest of mangos

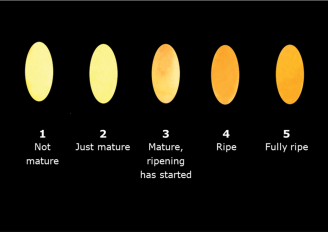

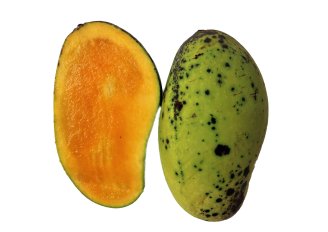

Mangos are climacteric fruits. This means that, once mature, they will ripen further after harvest. Mangos are often harvested when they are still green and firm, so they can reach distant markets. On the other hand, they must be sufficiently developed to be able to ripen and reach optimum quality later in the supply chain. Determining the right harvest moment is therefore important for the eating quality and marketability of the mangos. Good training, instruction and monitoring of individual pickers can ensure a good starting quality. Another important point of attention for the mango harvest is the latex flow from the stem. If sap from the cut stem comes into contact with the fruit skin, it will result in skin burns. Therefore, the harvesting procedure also includes the so-called de-sapping of the fruit.