Controlled ripening of bananas

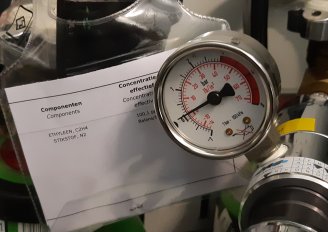

In order to deliver bananas at the desired stage of ripeness to retailers and ultimately to the consumers, controlled ripening takes place. Controlled ripening takes place in so-called “ripening rooms” or “banana rooms” in special ripening facilities or in the distribution centre. In these rooms, ethylene is released at a controlled temperature and humidity. Experts adjust the details of the ripening program to the maturity of the batch and the planned delivery to retail

Controlled ripening close to the market

Bananas are harvested in tropical regions in the green stage. After overseas transport, the bananas need to undergo a ripening process to become ready for consumption. This ripening towards a ready to eat banana takes place close to the market in the countries of destination. The application of ethylene in sealed ripening rooms initiates the ripening. This artificial ripening process is well controlled with to aim to providing uniform ripening bananas with a bright yellow colour and a good flavour when reaching the consumer.