Dealing with ripening and ethylene

Ethylene is a gaseous compound also called the “ripening hormone”. It is present in the air in an extremely low concentration, often not even detectable. Yet this gaseous molecule is very important for the ripening of many fruits. Most fruits produce ethylene to start the ripening process. The effect of ethylene can be seen as positive if it leads to ripe and tasty products. Sometimes ethylene is even artificially added to regulate ripening. However, in many cases the presence of ethylene is undesirable. It limits the storage time if the fruit ripens too quickly and becomes overripe. This applies to products such as apple, apricot, avocado, kiwi, melon, papaya, pear, peach, plum and tomato.

Ethylene and ripening

Ripening is the process by which fruits become attractive with changes in flavour, colour and texture. This is a desirable process for many fruits, making them visually appealing and flavourful. However, ripening can also be seen as quality loss. The importance of ethylene in ripening is most evident from its stimulating effects on respiration, ethylene production, softening and coloration. The ethylene effect on ripening can depend on the commodity, temperature, ethylene concentration and exposure time. Controlling ethylene can be critical during postharvest storage as ethylene can decrease storage potential, shelf life, and increase susceptibility to pathogens.

Ethylene production by fruit

Horticultural products can be classified according to their ethylene production. Ethylene production varies between different types of products. There is no direct link between a product's ethylene production capacity and its shelf life. Strawberries, for example, have a low ethylene production, but also a short shelf life, while apples (depending on the variety) usually have a high ethylene production and can be stored for a long time. Look here for a table with a list of products and an estimate of the extent of ethylene production.

Ethylene sensitivity of fruit

If ethylene-sensitive products are exposed to ethylene, this can have disastrous effects. Ethylene can be physiologically active in very small amounts, even below 0.00001% (=0.1 ppm or 100 ppb. The ethylene effect not only depends on the concentration, but also on the exposure time and temperature.Ethylene production and ethylene sensitivity are not always related. Products that do not produce large amounts of ethylene themselves can be sensitive to ethylene and therefore be affected by external sources of ethylene. An example is unripe kiwi. Look here for a table with a list of products and an estimate of the degree of ethylene sensitivity.

Ethylene during storage

The extent to which ethylene is produced depends on the temperature: less ethylene is produced at low temperatures. However, ethylene is still produced during storage at low temperatures. This can accumulate in the cold stores. The effects of ethylene on fruit quality are usually small at low temperatures. But for fresh produce that is sensitive to ethylene ripening, it is important to minimise ethylene levels in the storage areas to limit unwanted ripening and aging. There are several techniques for removing ethylene from storage areas.

Reducing the ethylene effect in practice

More information about situations in practice?

Ripening programs and ready-to-eat concepts

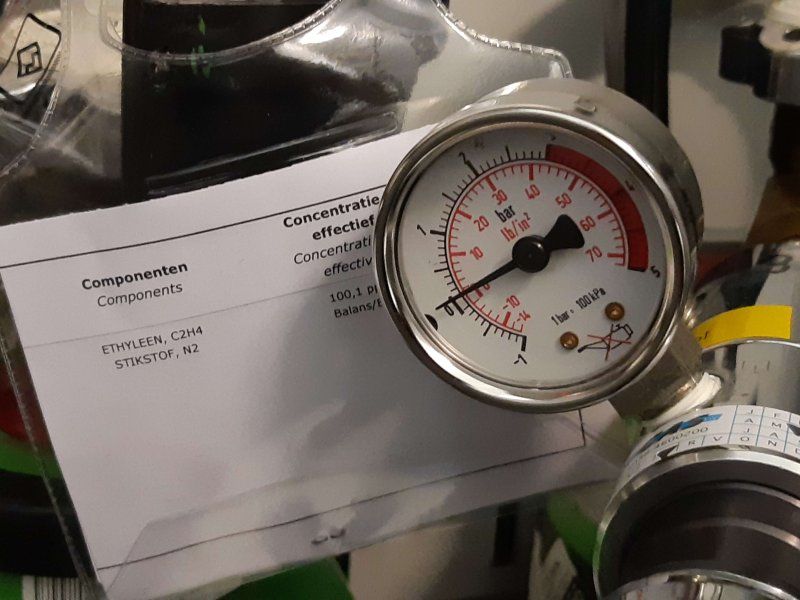

In some cases, it is desirable to artificially initiate fruit ripening. Ethylene gas can be used on climacteric fruits to stimulate the production of ethylene by the fruit itself. The best example of this is the banana ripening room, where ethylene is used to start the ripening process of green imported bananas. Such ripening programs, often a combination of ethylene and higher temperature, are also used for ripening avocado and mango. Ethylene gas can also be used to degreen citrus fruits, for example. In such a case, the breakdown of chlorophyll is accelerated, while the ripening process itself is not affected. The aim is to offer the consumer a more uniform and attractive product. Sometimes this is also specifically marketed as "Ready-to-Eat".

Ethylene sources and detection

Ethylene sources can be surprising because they are not always from plant products. It can also be released during the combustion of petroleum products (think of a non-electric, gas-powered forklift truck operating in the storage facility, or diesel engines of trucks that load/unload). It is important to measure the ethylene concentration of the air when using equipment that burns gasoline, as using it can increase the ethylene concentration to levels that affect the fresh product.Measuring the ethylene concentration is strongly recommended. Ventilate if necessary. The advice for distribution centers is usually to stay below 500 ppb. There are several ethylene detectors on the market.

Ripening mechanisms of fruit

More information?

Wageningen Food & Biobased Research is a contract research organization that works together with companies, government authorities and other knowledge institutes. Postharvest consultancy is one of our areas of expertise.

Do you want to know more about dealing with ethylene and ripening? Please contact our experts.

FreshKnowledge Team